All that is required to do this hydroforming, technically "low pressure twin plate hydroforming", is some BSP fittings, a modified trigger to a pressure washer (which are often rated upwards or 70bar) and 2 flat patterns of a shape you want to hydroform that have been welded around the seams.

To hydroform a bike frame I have decided to aim for the geometry as used in the 29er that I made previously. Achieving the desired geometry is simple in CAD/drawings after the hydroforming process is completed, however transforming this to a flat pattern that can be cut out of steel sheet is more complex.

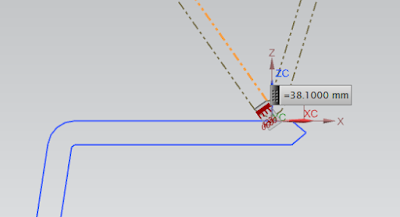

As has been shown by Colin Furze there is a difficulty when transferring a flat pattern into a 3d form, this problem comes with curves, radii and bends. The way to do this is making the width of your plate half the circumference of the tube overall diameter that you require (Fig. 1 and Fig. 2). When considering bends and curves you have to consider the desired finished bend radius, when you think about it, it is the arc length of the curve that stays constant for both the inside and the outside radii, regardless of the flat pattern or blown up piece, this being how to work out your flat pattern (setting both the same, Fig 3. and Fig 4.).

|

| Fig. 1 - Overall Diameter Desired |

|

| Fig 2. - Flat Plate Equivalent |

|

| Fig 3. - Arc Length of the Bend Around the Bottom Bracket at Desired Tube OD |

|

| Fig 4. - Arc Length of the Bend Around the Bottom Bracket on Flat Pattern |

As such it is much simpler to build it in a single "tube" that is designed to fold back on itself, this can then be welded with only a single weld afterwards. This can be seen below with the desired geometry outline along with the 2D profiles that are required to achieve this.

Unfortunately, as a result of potential issues with buckling and folding, I shall not be trying to hydroform a head tube, bottom bracket, brake mount or drop outs. I shall also by forming 3 pieces (2x chainstays [Fig. 6], 1x front triangle [Fig. 5]) and then using a post welding/brazing process to complete the frame using my previously made frame jig.

Unfortunately, as a result of potential issues with buckling and folding, I shall not be trying to hydroform a head tube, bottom bracket, brake mount or drop outs. I shall also by forming 3 pieces (2x chainstays [Fig. 6], 1x front triangle [Fig. 5]) and then using a post welding/brazing process to complete the frame using my previously made frame jig.

No comments:

Post a Comment